FusionENG designs and manufactures

customized Mechanical and Materials Testing Instruments for

the specific needs of research institutes and universities.

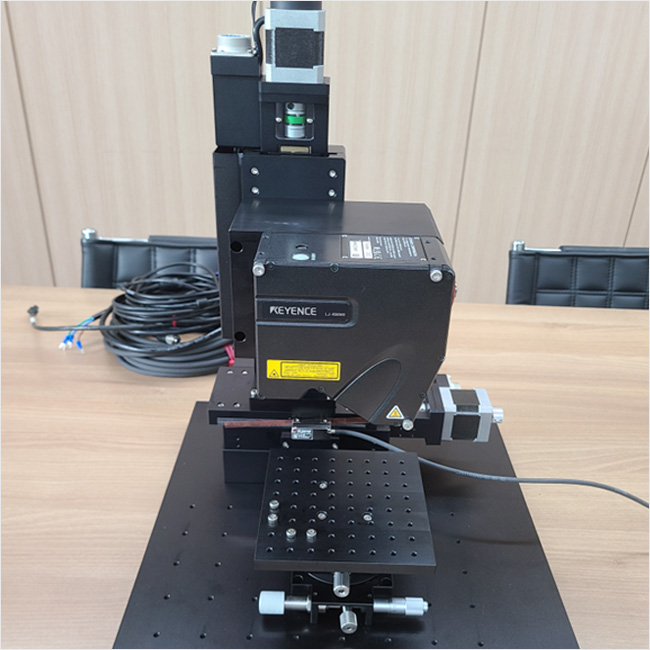

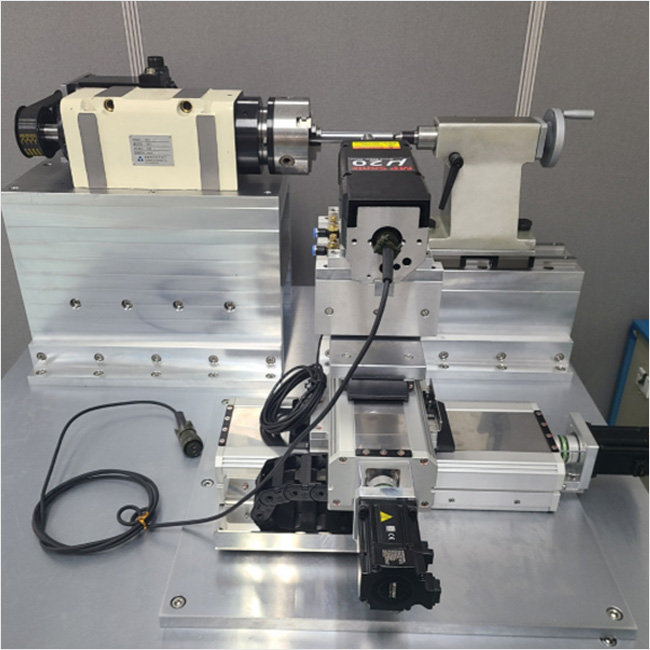

By integrating optical and laser sensors with precision actuators,

the systems acquire high-resolution multi-physical data

including micro-displacement, load, and vibration.

- Analysis-Driven Design : Develop prototypes to meet the specific specifications customers want with the CAD/CAE library developed by FusionENG

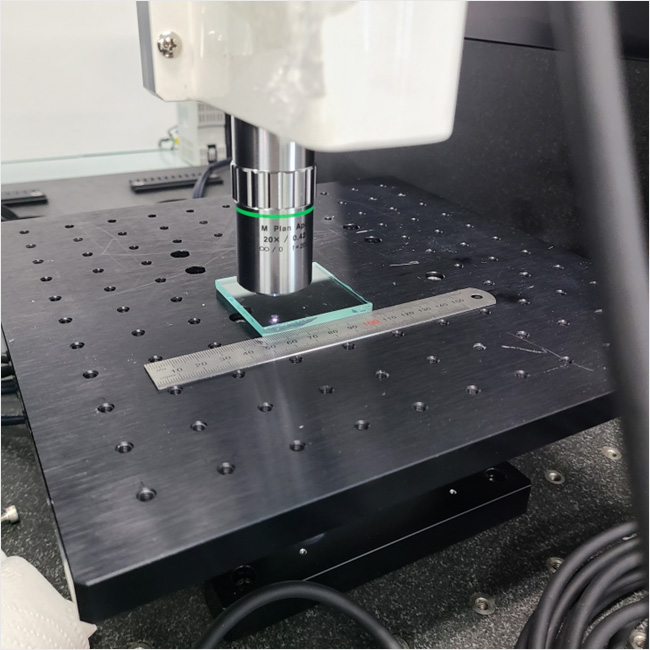

- Vision-Based Measurement : Using OpenCV and proprietary algorithms, the systems implement

video-based strain, crack detection, and 3D DIC measurement with real-time feedback control.

- Integrated Software : Motor control, data acquisition, analysis and reporting are integrated

in a single platform.

Supports industrial communication protocols such as Modbus and EtherCAT,

as well as automation scenarios for maximum efficiency.

Development Process

① Requirement Definition

Define target performance, environment, and specimen

② Design & Analysis

Incorporate CAD/CAE-based structural analysis

③ Manufacturing & Assembly

Integrate precision actuators and sensors

④ Software Integration

Combine control, acquisition, analysis, and reporting

⑤ Installation · Training · A/S

On-site setup, stabilization, and user support

From planning to installation and maintenance, we provide a one-stop solution,

ensuring fast and reliable realization of any type of specialized testing equipment.