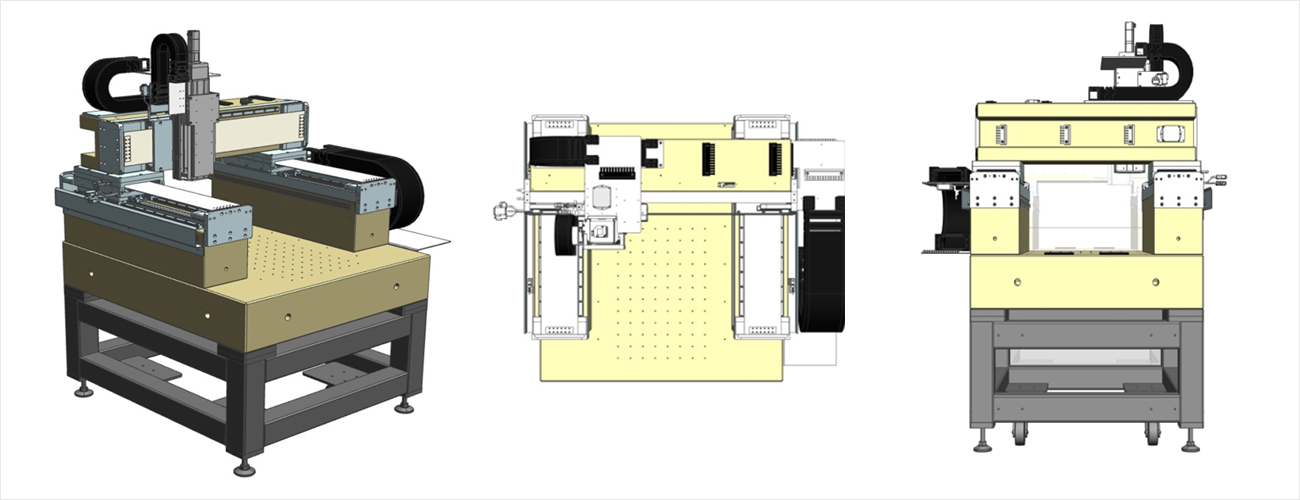

The Contour Measurement Instrument features a 5-axis structure in which the linear X, Y, and Z axes perform precise positioning,

while two leveling axes correct the sample's pitch and roll to ensure that the scan and cutting planes are perfectly aligned with the reference surface.

By automating leveling and reference alignment, the system achieves 2–3 μm flatness and precision across the entire measurement area,

minimizing operator dependency and setup variability.

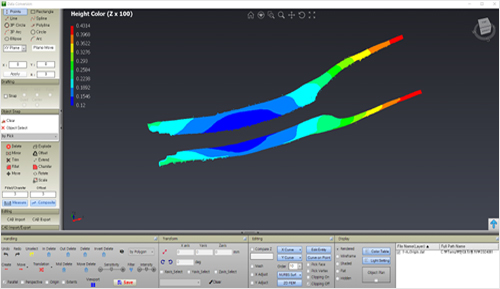

Measurements are performed using a nanometer-class confocal laser displacement sensor that suppresses high-frequency noise while maintaining sub-micron resolution.

A closed-loop linear stage with high-precision encoders reduces positional drift and ensures consistent positioning quality during repeated traverses.

The optimized optical system and vibration-damping design improve the signal-to-noise ratio (SNR), enabling reliable surface-profile acquisition even during ultra-fine incremental movements.

For long-term operation, temperature compensation and periodic self-calibration stabilize readings against environmental variations.

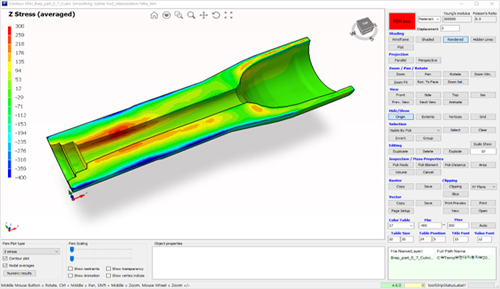

The resulting displacement maps, when used as input for Contour Method FEA back-calculation, exhibit minimal distortion and excellent reproducibility,

greatly enhancing the reliability of the derived stress maps.

In conclusion, the integration of the 5-axis architecture with nanometer-scale metrology ensures stable, field-proven micron-level accuracy,

delivering industrial-grade resolution, repeatability, and reliability throughout analysis, validation, and reporting.

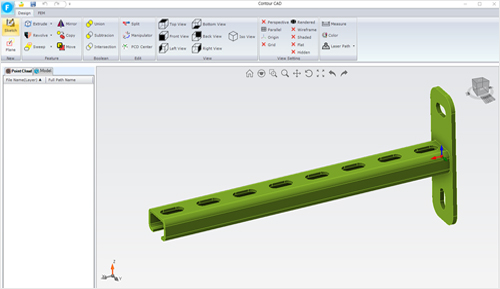

Contour Suite integrates Transform–CAD–FEM into a unified workflow, enabling seamless execution of data preparation, measurement, and analysis.

This integrated software stack operates stably even for complex shapes and large components, significantly minimizing the total test time for preparation → analysis → reporting. Also providing reliable, data-driven quantitative results.